In July, APM Steam reported to International Paper's Ticonderoga Mill site to perform a generator field swap. Our APM Steam team consisted of nine APM Millwrights and three Certified Mechanics per shift at the site.

Read MoreAPM Team,

Please see the below video for our response to the feedback and planned actions based on our Employee Experience Survey.

Improve Work / Life Balance:

Identify Business “Periods”, including peak and blackout periods

Identify Backups for all Positions

During the Spring Outage Season, the APM Boiler Canada team deployed in Lebel-sur-Quévillon, Québec, Canada, at Nordic Kraft Pulp and Paper Mill, responding to two failing smelt spouts. Smelt spouts are extremely critical to the chemical recovery process of the pulp and paper mill industry. Restoring the functions of this critical equipment as soon as possible was vital to our new customer.

Read MoreTwo weeks past we hosted ~40 new Superintendent candidates at our LDC. It was great to have in person classes back. Even with COVID protocols in place and followed, there was an energy in the LDC I missed and quickly found.

Read MoreDuring the Lean Week that occurred globally back in January, teams joined in activities to identify and improve current standard work procedures. APM participated in approximately five kaizens that week to create improvement in efficiency within the standards in place. The teams kept safety at the forefront with every lean initiative they sought while retaining the quality of work performance. To allow for greater productivity and cost savings, team members encouraged each other to think outside of the box.

Read MoreEarlier this summer we launched our first ever employee experience survey. The goal for this process was to better understand what YOU value – where we deliver strongly on your expectations and where we could improve the experience you have in a meaningful way.

Read MoreAPM Gas, Boiler, and Specialty Services brought full force craft-power to TVA Paradise Combined Cycle Plant back in April. The heavy-hitter APM craft team consisting of Superintendents, Operating Engineers, Boilermakers and Millwrights, knocked out multiple extensive work scopes across three units and a Toshiba steam turbine generator.

Read MoreOver the past week I have been “catching up” on some actions and some reading. In my read box was this article titled On Followership from our friend and mentor Paul Balmert.

Read MoreOur business strategy for excellence is founded on the Safety Keystone philosophy, i.e., that our excellence starts and is rooted in our safety disciplines. If we deliver safety excellence, then we deliver quality, productivity, etc. And our expectation is that the Safety Keystone philosophy will deliver an excellent experience for our employees, with zero injuries (or to state it positively, all home safe 100%).

Read MoreAPM, FieldCore, and GE assembled as a One GE Field Service Solution to deliver full maintenance work to nine steam turbine rotors at APM’s Leadership Development Center (“LDC”) for two customers located at three separate sites. This is the first time APM has completed maintenance service of this magnitude at their headquarters located in Pasadena, Texas.

Read MoreThis past week we had the opportunity to engage with one of our most important stakeholders – our Customer (Exelon). The conversation provided an opportunity to give and receive candid feedback on things we do well and things we can do better. Below I share a few reflections from our conversation.

Read MoreThis week, the last week of May, is bookended by the Victoria Day & National Patriot’s Day holidays in Canada and Memorial Day in the USA. It marks the end of spring, school, little league baseball, and brings the attention to summer, pool parties, and vacations. It also usually brings to closure the spring outage season.

Read MoreWe are enormously excited to announce APM Boiler Canada as this year's repeat recipient of the Tripartite Zero (Recordable) Injury Turnaround Award! APM Boiler’s top-tier health and safety emphasis received major attention at the TransAlta Sundance – Unit 6 Turnaround where over 61,000 craft hours were completed – injury free.

Read MoreThis commonly stated quote was repeated in a meeting I joined in Atlanta this past week. The meeting was a review of recent safety performance. Using a lean tool called the PSR (Problem Solving Report), we dug into the data to identify trends, with the goal of (i) taking immediate action to prevent injuries today and (ii) taking long term action to get better at preventing injuries in the future.

Read MoreThis next week we devote our messaging to Lean. I encourage you to engage in the Lean messaging as Lean is permeating every facet of our business. If Safety is our keystone by which all other disciplines are rooted, then Lean is our operating system for how we execute the business.

Read MoreNext week is our bi-annual discussion with you about one of our core values, Integrity. Our discussion will include email communications, jobsite toolbox talks or pre-meeting culture moments, and daily OutageBuzz Facebook, Instagram, and Twitter social media profiles. Everyone in APM = YOU! are encouraged to engage in our discussion.

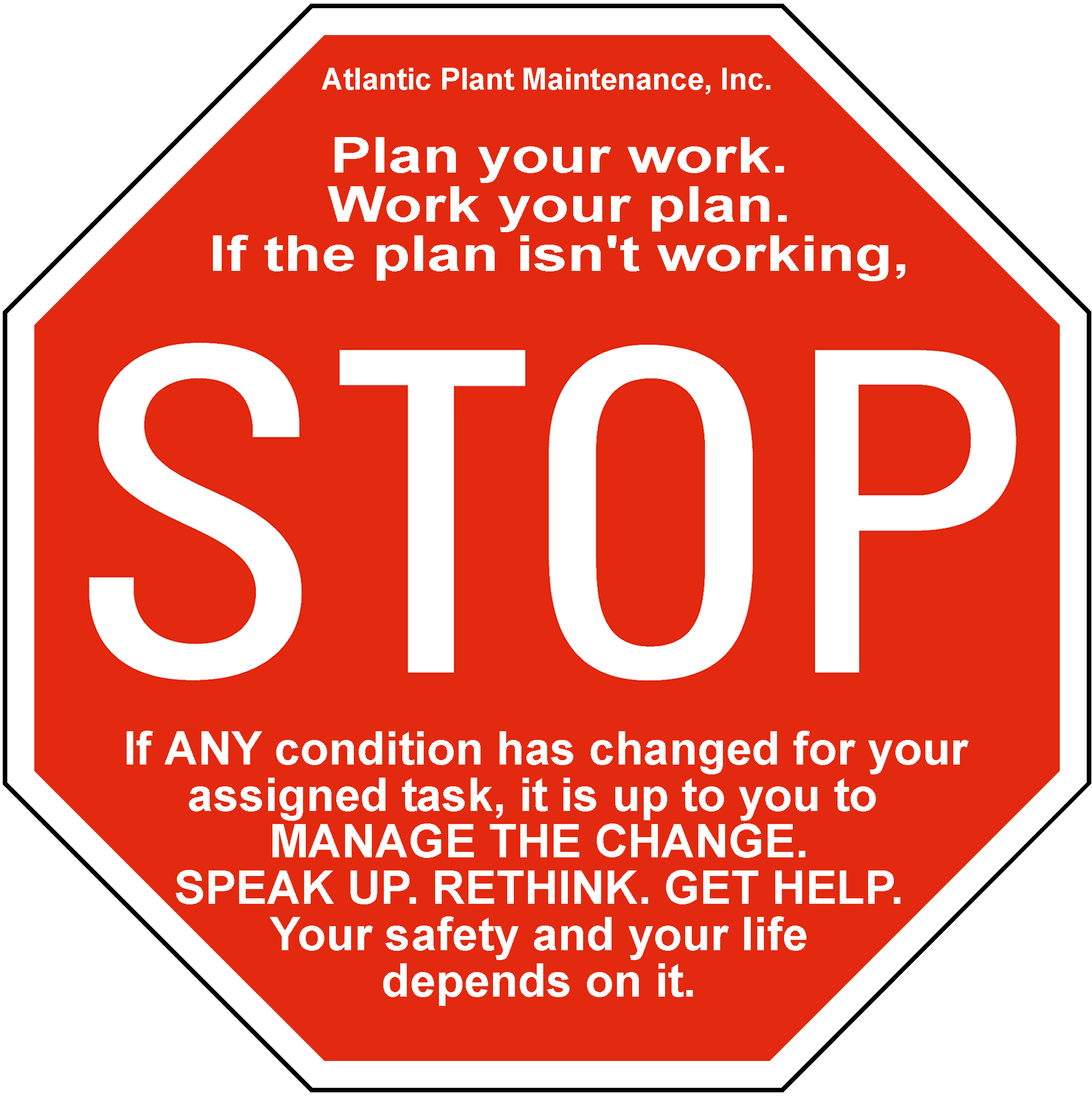

Read MoreAPM Gas Power Services in the South, led by Superintendent Daryl Hale, recently conducted an impactful STOP Event in March. Located in Louisiana, the Team’s work scope entailed a major inspection as well as an AGP upgrade.

Read MoreThese past few weeks have brought two realities to our APM. First, we are doing a lot of work. On average we are employing over 2500 craft working over 150K hours on over 200 job sites each week. Second, we have seen a cluster of injuries to our teammates. Fortunately all are recovering well…

Read MoreKaizen, Our Way of Life

What is Kaizen? It means change for better. It’s a Japanese term for continuous improvement and has been embraced by many organizations focused on delivering value to the customer, while eliminating waste, improving productivity, and achieving sustained continual improvement in their identified activities and processes.

Read More