APM Canada

Our Services

Gas Power:

Services:

o Combustion Inspections

o HGP

o Major Inspections, 2.6+, .05 upgrades

o D11, A14, A10 Combined Cycle units

o Valves (MSV, CV, RSIV)

o Generator Inspections

o Gen Magic

o Bearings

o Alignment

o Maintenance and installation of gas and combined cycle steam units.

o B/E Class, F Class,

o GT Rotor Major Inspections

o GT11, GT24, and Alstom Combined Cycle Steam Units

Technologies:

o AGP Upgrades, Casing Replacements, Exhaust Ducts Upgrades, Turning Gear Upgrades, Liquid Fuel Water Flush Upgrades

o Superintendent Led Turnkey Outage Services on Legacy Technology

o Balance of Plant Maintenance: Auxiliary Equipment, Pumps, Motors, Inlet Air Filter Replacement

o New Equipment Installations

o Technical Advice and Guidance Services

o Additional Custom Services provided by APM Specialty

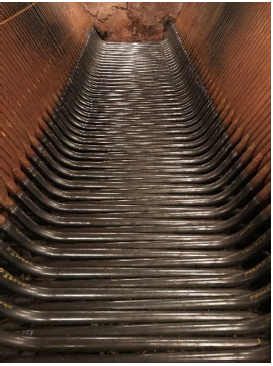

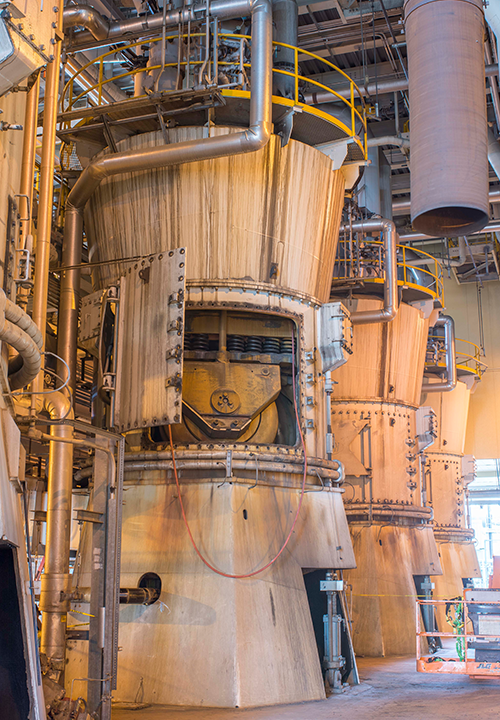

o HRSG Installation & Maintenance Services provided by APM Boiler

Oil, Aero & Gas Services:

- Customized Field Services for Petrochemical and Industrial Plant Outages (Planned and Unplanned)

- Crating Services

- Heavy Duty Gas Turbine

- Installation, inspection, and maintenance

- Aeroderivative Gas Turbine

- Installation, maintenance for LM2500, LM6000, including LMS100 booster work

- Compressor

- Installation, inspection, and maintenance

- Steam Turbine

- Installation, Inspection, maintenance, and steam chest replacement

- Hot Gas Expander

- Installation and commissioning

- Pump inspection and repair

- Gearbox maintenance and refurbishment

- Borescope inspection and laser alignment

- Balance of Plant Maintenance

Steam:

Services:

o Large Fossil Steam Turbines: Major/Minor Inspections

o Industrial Steam Turbines: Major/Minor Inspections

o Maintenance and Upgrades on Generators

o Valve Inspections

o Bearing Alignments

o Balance of Plant Maintenance

o Qualified Onsite Supervision and Craft Support

o New Equipment Installations

Products:

o Turbines:

§ GE, Alstom, Hitachi, Westinghouse, Brown Boveri, Siemens,

o Generators:

§ GE, Allis Chambers, Brush, Brown Boveri, Alstom, Hitachi, Siemens, Westinghouse

o Valves:

§ MSV, CV, RSV, Governor, Digital Upgrades

Steam Nuclear:

Services:

o Complete maintenance and installation services for nuclear and fossil steam turbines

o Bearing Change Outs

o Open, Clean, Inspect, Close [OCIC]

o Inspections: Major / Minor

o Bearing Change Outs

o Blade / Bucket Replacement

o Borescope Inspections / NDE

o Emergency Response

o Balance of Plant

o Tooling - Custom, Containerized & Portable

o Detailed Outage Planning

o Field Machining / Balancing

o Foreign Material Exclusion (FME) Procedures

o OSHA Compliant Safety Program / On-Site Safety Certified Professionals

o Turnkey Outage Services / Scheduled Maintenance / Forced Outages

o Planning / Scheduling / Coordination

o Steam Path Component & Generator Repairs

o Generator

o Field / Rotor Rewind / Stator Re-wedge / Rewind

o Safety Focused - OSHA Compliant Safety Program

o Quality & Document Driven

o Nuclear Outage Compliant

o Turbine Valve Inspection / Overhaul / Repair

Turbines:

o GE, Alstom, Hitachi, Westinghouse, Brown Boveri, Siemens, Reactor Feedpump Turbines

- Generators:

o GE, Allis Chambers, Brush, Brown Boveri, Alstom, Hitachi, Siemens, Westinghouse

- Valves:

o MSV, CV, RSV, Governor, Digital Upgrades

Electrical and I&C:

Electrical Services:

o 24/7 Emergency mobilization response service

o Equipment installation, modification, upgrades, troubleshooting and repairs

o Equipment maintenance

o On-site design, fabrication and installation of supports, conduits and raceways

o Cable testing pre and post installation when requested

o Cable installation, modifications and repairs per print, procedure or per OEM drawings

o Wiring checkout per OEM drawings

o Terminations of cable per print and design

o Acceptance testing support

o Low & high voltage electrical terminations

o Electrical Maintenance Program (EMP)

o Material and tooling management

I&C Services:

o Instrumentation installation, repair or replacement

o On-site design, fabrication and installation of supports, conduits and raceways

o Instrumentation cable installation, modifications and repairs per print, procedure

o Transmitter & controller calibration

o Instrument loop testing & calibrations per OEM specifications

o Programmable Logic Controller

o Start-up testing and support

o Instrument Maintenance Program (IMP)

o Under Vessel instrumentation repair and maintenance

o Wiring checkout per OEM drawings

Shop/Warehouse:

o Gearbox repairs

o Valve repairs.

o Small steam overhauls

o Parts storage

o 10-ton crane

Management

Craig Mosier, Operations Division Manager

012.345.6789 | craig.mosier@apmdelivers.com

Ben Storie, Operations Division Leader

587.334.5785 | ben.storie@apmdelivers.com

Derek Steele, Operations Division Leader