Get the Buzz ... APM Steam Fossil Overcame Challenges Through Coordination and Vigilance at Little Gypsy Station Louisiana

Estimated Read Time: 5 minutes

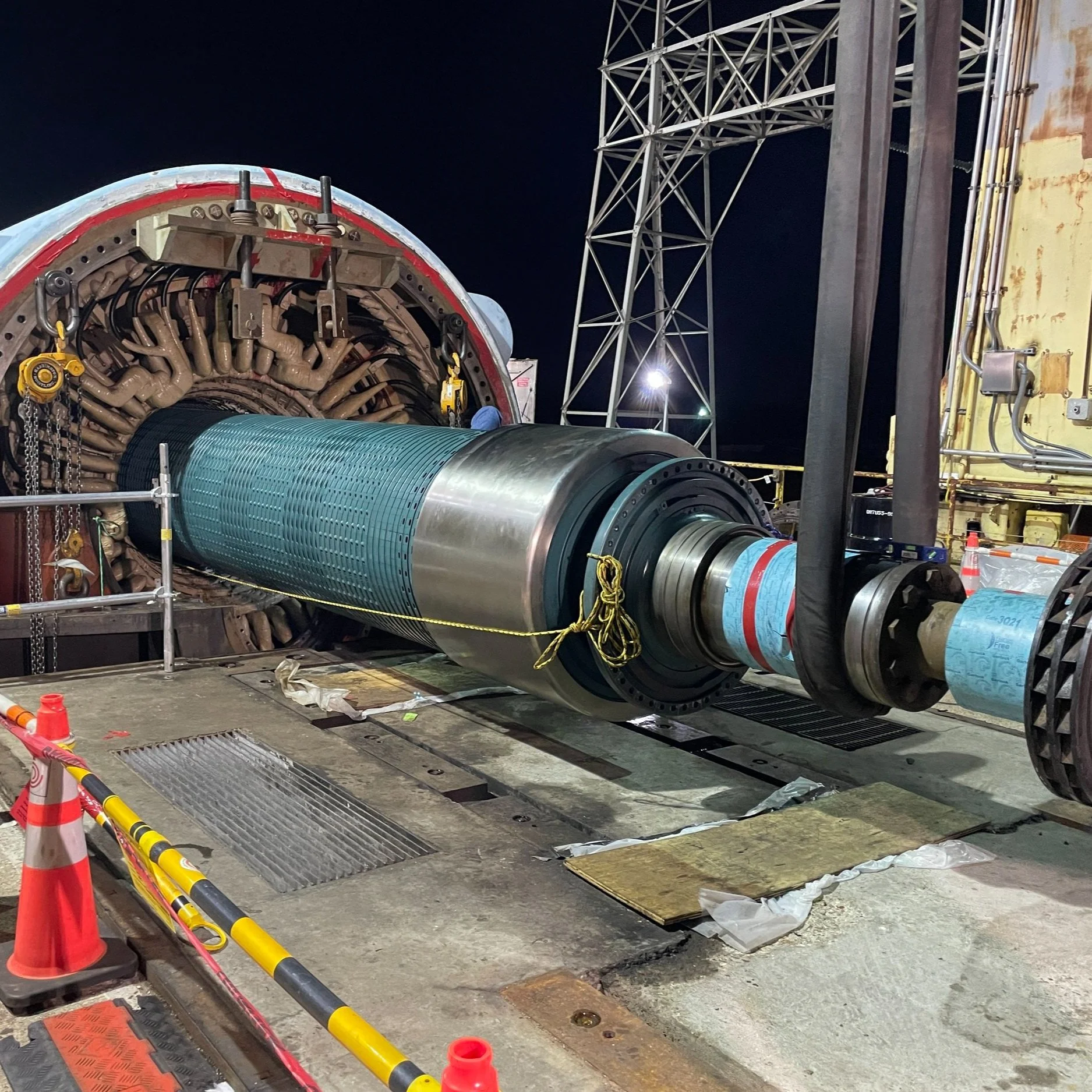

At Entergy Little Gypsy station in Montz, Louisiana, Steam Fossil performed a HP/IP disassembly from December 1st through December 19th, 2022. They then remobilized on January 3rd, 2023 for the HP/IP Major/Outer Shell Repair and reassembly and a generator rewind. After demobilizing on July 7th, the team revisited the site for the last time on October 4th to finish the generator reassembly and concluded the job scope on November 3, 2023. Throughout the multiple remobilizations, Steam Fossil completed over 45,000 manhours with ZERO recordable injuries or quality events!

Communication and planning proved to be invaluable for the success of this outage. Between the mobilization and demobilization movements, limited floor and crane bay spacing, and loading and unloading trucks with very limited spacing around the plant, every task required intense coordination and attention to detail. In addition, with the various craft and other trades personnel on site -- Millwrights, Pipe Fitters, On Site Services, Specialty Services Technicians, Analytic Stress, Generator Specialists, Carpenters, Field Engineers, and Technical Field Advisors -- having flexibility and coordination among the team was also essential.

Working in this unique situation required the APM team to be observant daily and take precaution with keen awareness of their surroundings. This heightened attentiveness worked in their favor for an important STOP moment. While removing the main steam inlet flanges during the disassembly of the HP/IP unit and preparing to lower from the outer shell, the APM team found out that the pipe was not supported by pipe hangers. All work was stopped and cribbing was put into place on the ground floor to support the piping throughout disassembly. The MSI flanges weighed approximately 17,000 lbs., so if not addressed, the unit could have dropped, causing piping stress, welds breakage, and extensive damage. This is not something typically investigated, so the team went above and beyond to pay special attention during unit disassembly, get better visuals, and catch the issue before damage occurred.

The APM team totalled around 36 craft employees with 15 Millwrights per shift including Superintendents, Safety Champions, and Project Superintendents. On the day shift, Thomas Grayson was the Superintendent and Mark Angel was the Technical Field Advisor. For the night shift, Brennon Morris was the Superintendent and Jaime Ratliff was the Technical Field Advisor. Thanks to the extensive coordination among the leaders of the outage and the flexibility and patience from everybody involved, the logistics of mobilization, demobilization, and scheduling contributed to the success of this outage instead of acting as a hinderance.

We’d like to appreciate the following individuals for their exceptional performance on this job:

Jonathan (Moe) Evans, Subject Matter Expert and Foreman, kept the job moving forward with safety first and led the crew with expertise on the mechanical side.

Millwright Operator, Merlin Smith, with his expertise on crane safety. The crane was an old-style gantry crane with older style levers and foot pedalling functions. This combined with very limited floor spacing while making any lifts made Merlin’s expertise vital.

Safety Champions, Ron Hinds and Regina Smith, with their guidance on the deck, always keeping the craft safe, and keeping all hazardous permits, shareholder and customer policies up to date.

Thank you to our APM Steam Fossil team for your exceptional coordination, attentiveness, and safety mindset on this outage!